Process

HPS offer a full range of process engineering services from consultancy and concept studies, through front end engineering, to detailed design and EPCm.

Working collaboratively and drawing on their operational experience, our team of process engineers always strive to understand the needs and drivers of our clients delivering appropriate, fit for purpose solutions.

Our Process Engineering services include the development and delivery of:

-

Process Block Diagrams, PFDs and P&IDs

-

Heat and mass balances

-

Process descriptions

-

Process data sheets and specifications

-

Process instrument data and schedules

-

Control philosophies

-

Utility studies and balances

-

Pressure relief systems

-

Site investigations and troubleshooting

-

Commissioning procedures

-

Commissioning support

Process Safety

With extensive exposure to highly regulated industries, our trained and experienced staff offer a range of process safety services, both on a consultancy basis and in support of our projects.

Our process safety services include:

-

Hazard Studies 1 to 6, including HAZID, HAZOP and retrospective review – chair and scribe

-

Relief stream design, verification and audit

-

Hazardous Area Classification (HAC)

-

DSEAR risk assessments

-

SIL determination (LoPA)

-

Process basis of safety

Validation

Our mission is to serve our clients with a reliable and flexible CQV solution. Everything we do is customer focussed and we take great pride in helping our clients deliver projects to schedule. Our engineers come from operational backgrounds, enabling them to integrate into site teams seamlessly. When customers work with us they feel as though we are part of the site team. We are solutions focussed and bring access to the HPS design team for getting over those unexpected bumps in the road.

Our Validation services include:

-

Requirements Definition

∙ URS development

∙ System risk assessments

∙ Validation master planning

-

Design Assurance

∙ GMP reviews

∙ DQ

∙ C&Q planning

-

C&Q Testing

∙ FAT / SAT

∙ IQ / OQ

∙ PQ

-

Handover

∙ Summary reports

∙ Traceability

∙ Acceptance & release

Project Management

Our mission is to help you get the best return on your capital investment. We will help you select the right projects and implement them correctly from the start. With our project control focus, we ensure tight alignment with your business case. We do this by establishing and controlling the right baselines for project scope, schedule, risk, and cost. We place an emphasis on front-end loading which ensures the selected baselines are optimal and predictable given your business drivers.

Earned Value Analysis or Earned Value Management (EVM Analysis) is an essential part of project management. The methodology allows our project managers to measure the amount of work done by the team members and evaluate the value of that work. The analysis is made beyond the fundamental review of the cost and scheduled reports of the project management. It helps our managers to get a deep insight into the intensity of the progress that has been achieved.

Change management is an important factor of HPS Project Management capability. With inflationary pressures, such as increases in material costs on EPC projects, the need for a robust change management process to deliver to cost and schedule has never been greater. There's no "one-size-fits-all" approach to change management – so there's no perfect way to lead it but to apply a set of principles to each project taking into account the stage of the project in its lifecycle.

Piping & Layout

HPS has a diverse team of mechanical and piping engineers and designers consistently producing innovative, robust and cost effective plant design solutions.

The layout group collaborates with client engineers, plant operators and other engineering disciplines utilising 3D Modelling tools to provide a fully coordinated plant design. Visual review tools allow all stakeholders to regularly review and input to the design through its development.

HPS constantly strives to embrace technologies which add value and accuracy to the design process and provide bridges between the design disciplines, suppliers and installation contractors.

Our Piping services include:

-

Option studies

-

Feasibility study – conceptual design

-

FEED study – basic engineering

-

Engineering design – for procurement

-

Detailed design – for construction

-

Construction supervision and support

-

Existing Plant Survey

∙ Traditional site measure

∙ Laser scan and post processing

∙ Topographical survey

∙ Specialist surveys such as drainage & GPR

∙ As-built layouts

∙ As-built P&IDs – both graphical and "intelligent" with embedded plant data

Our Piping deliverables include:

-

3D coordinated plant model

-

Pipe, valve, line item, insulation and associated specifications

-

Plot plans

-

Plant layouts – equipment location GA drawings

-

Piping arrangement drawings

-

Pipe support, location, details & schedules

-

Piping isometric drawings

-

Bulk and individual line material take-off

-

Miscellaneous mechanical details

-

Mechanical procurement packs

-

Installation specifications

-

Vendor bid analysis

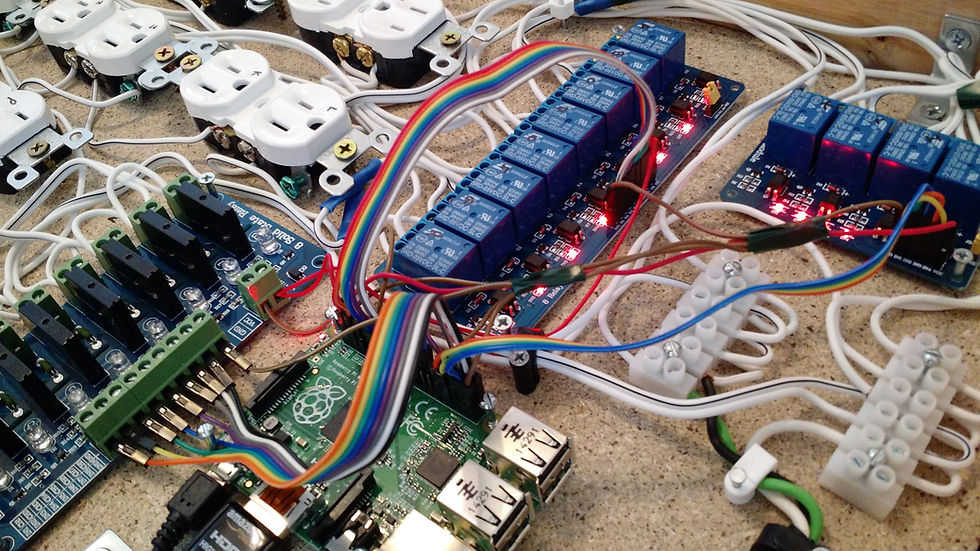

Electrical Control & Instrumentation

From production of the preliminary Single Line Diagrams (SLD's) and Block Cable Diagrams (BCD's), through to E,C&I commissioning, the HPS E,C&I team can cover all aspects of design. This includes but is not limited to, creating of the Functional Design Specification (FDS), instrument specification and production of software. HPS have the in house knowledge to work on both HV and LV systems.

At Hart Process Services our team of E,C&I Engineers and Designers have vast experience delivering all phases of projects from feasibility to commissioning across all process industries.

Our E,C&I services include:

-

Electrical Services

∙ LV design and specification

∙ Cable sizing calculations

∙ Load assessment and

power quality studies

∙ ARC flash surveys

∙ MCC design and build

∙ Earthing design

∙ Lightning protection design and specification

∙ Trace heating specification

∙ Electrical installation

specification

∙ Installation, testing and

commissioning

-

Instrumentation services

∙ Instrumentation

specification

∙ Actuated and control valve

specification

∙ Instrument installation

∙ Hazardous area design

∙ TUV functional safety

∙ Safety instrumentation

∙ Testing and commissioning

-

Control Services

∙ PLC and DCS system design

∙ PLC and DCS software

development

∙ PLC and DCS upgrades

∙ SCADA / HMI specification

and development

∙ Network architecture

development

∙ Industrial bus system design

∙ Control panel design and

build

∙ Network / server cabinet

design and build

∙ Testing and commissioning